Tags

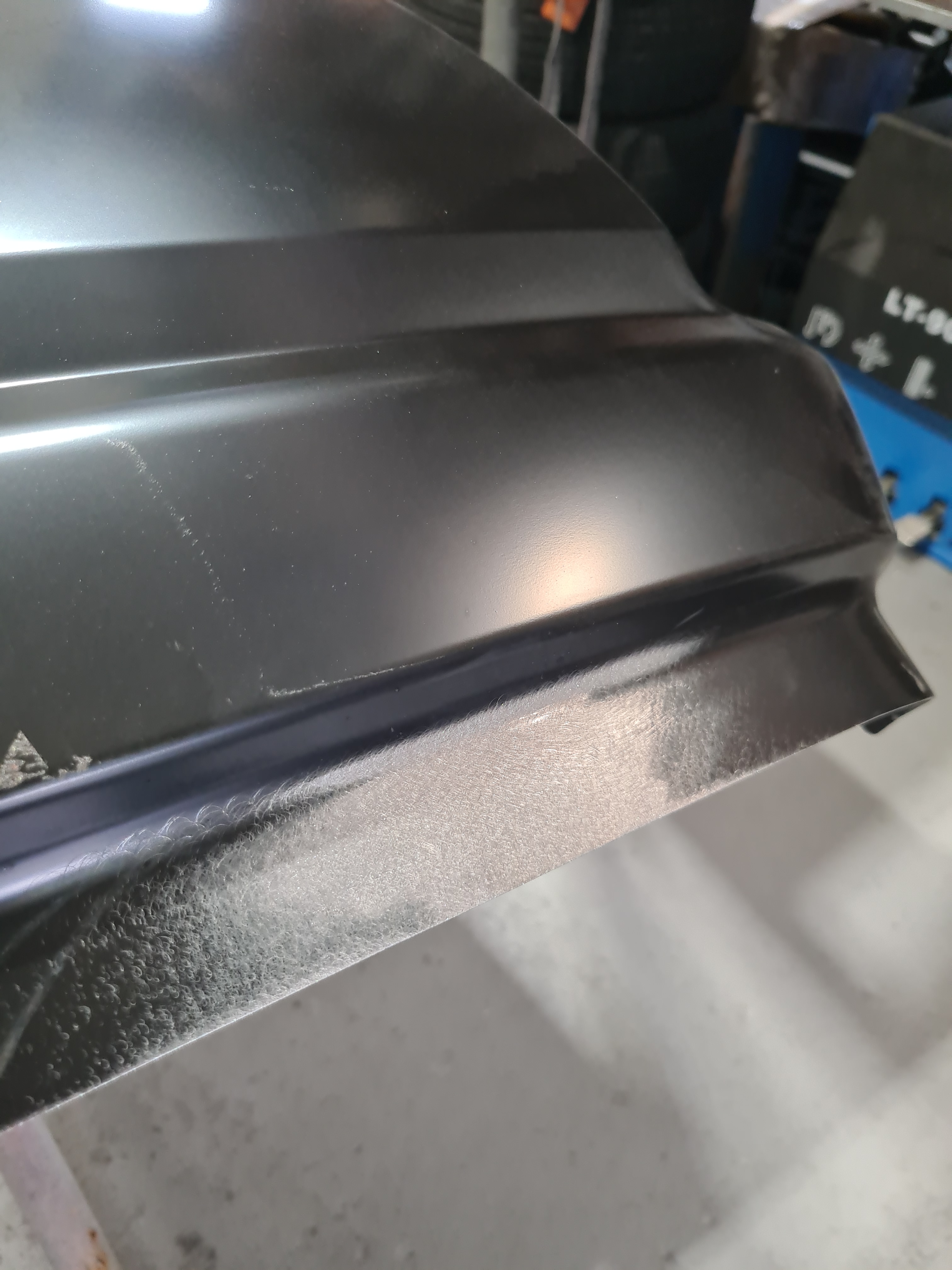

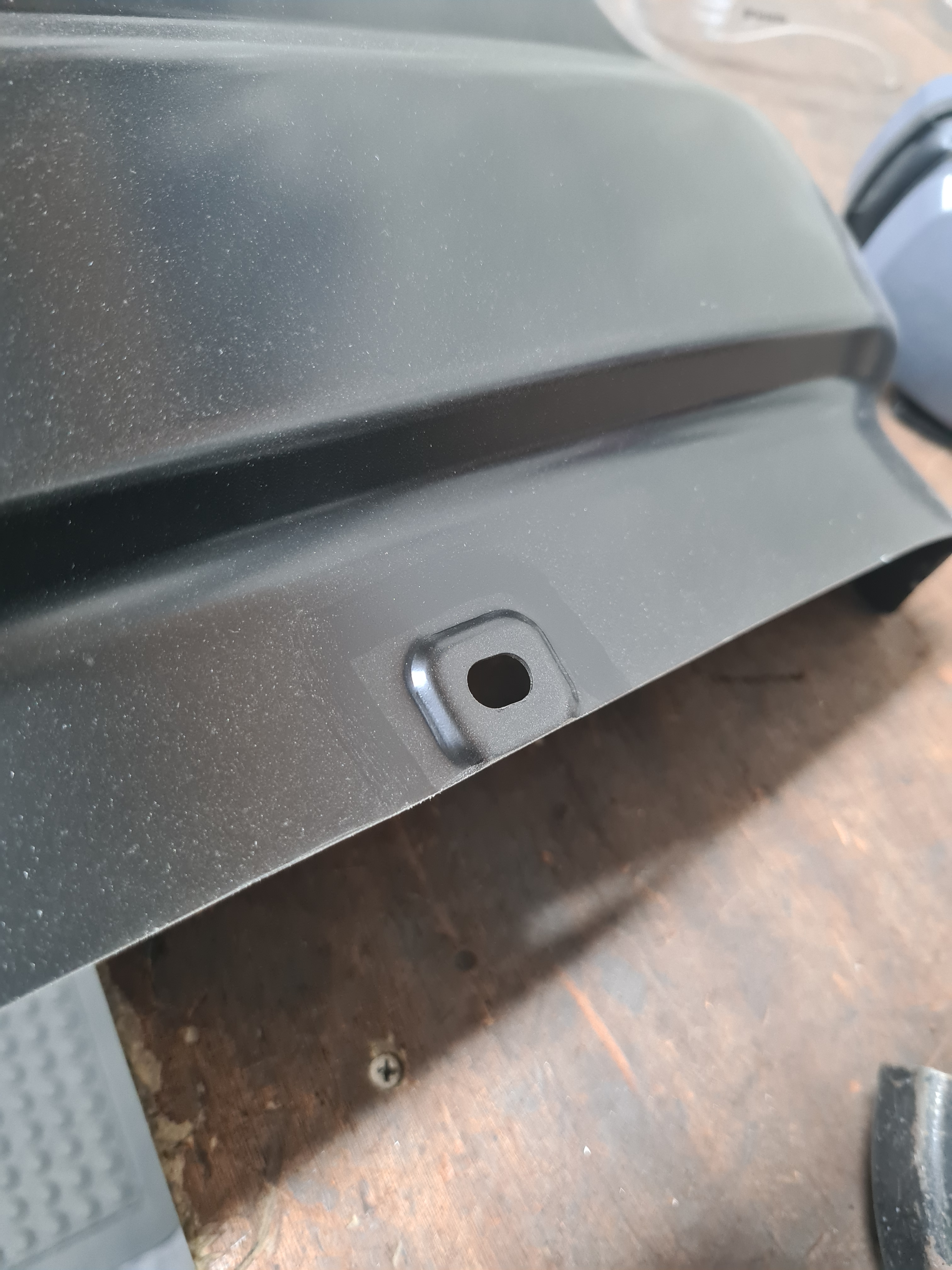

The car has run fibreglass rear over fenders ever since i first built this shell many years ago, but overs always have a wave to them and the bolts around the perimeter are a bit unsightly. For this next version of thr car i really wanted to step up the overall presentation and make it more respectable, afterall I’m try to go for that street driven driftcar look. So i purchased a pair of reproduction quarter panels and got to work swapping them onto the car, this was a task i was nervous to undertake, but the end results are better than i could have hoped for. As an added bonus i found some very poor rust repairs that had been done by the previous owner that are now in the bin. The next step will be grafting on the new metal flares to suit the wide wheels.